-

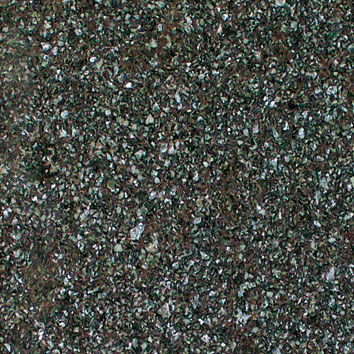

POLISHING

This technique gives maximum shine and a mirror finish to the stone, enhancing the tonalities and emphasising the contrasts in the veining, while providing great durability.

-

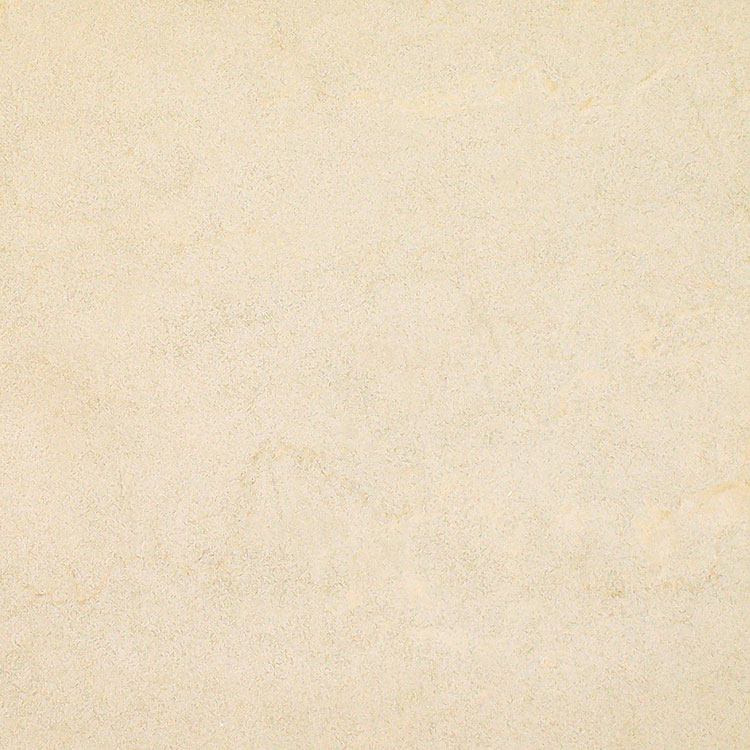

HONING

It gives a smooth, but not reflective surface, highlighting the colour of the stone while maintaining its opaque hues.

-

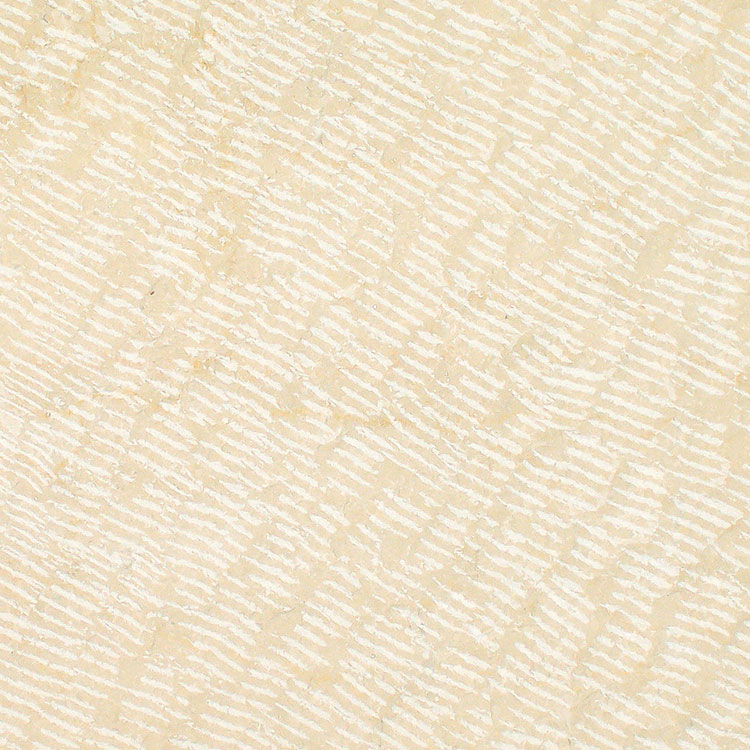

BRUSHING

A more recent method, which is a balance between practical and aesthetic requirements, creating a slightly rough and rugged surface with chromatic saturation of the stone, similar to the effects of polishing.

-

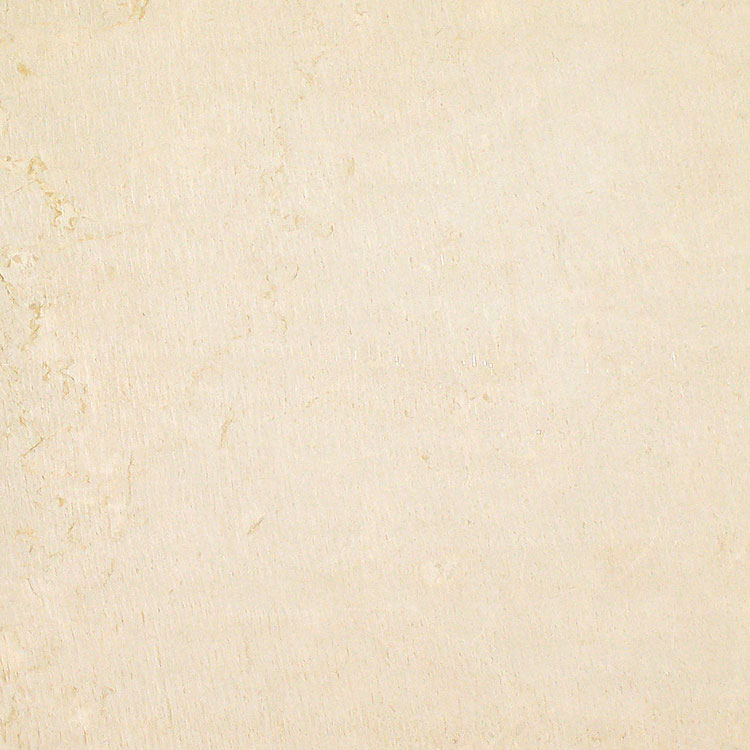

ANTIQUE FINISHING

A technique that creates a “worn” or “aged” appearance, imitating the effects of the passage of time.

-

FLAMING

Gives a distinctive rough and cratered look to the treated surface, with a surface similar to naturally aged stone.

-

WATER-JET SYSTEM

By using a high pressure water jet a rough surface similar to flaming is obtained.

-

BLUNTING

It is one of the most ancient techniques for surface treatment. It produces a coarse, uneven surface, marked by a series of recessed and relief areas of varying depth. The overall aesthetic effect is enhanced by the contrasts of light

-

BUSH-HAMMERING

Done manually in the past with a denticulated hammer, today it is carried out mechanically. It produces a rugged texture and a surface of dotted markings.

-

HAMMERING

Characterises the surface with elongated markings, enhancing light and dark effects. This is a traditional technique that can be carried out either manually or mechanically with different results.

-

SANDBLASTING

Performed mechanically by a sandblasting machine to obtain a coarse, whitened surface with a smoother finish than that obtained by percussion treatment.

-

GRAVING

Gives a finish characterised by parallel grooves which are normally not perfectly straight. This is a traditional method carried out by hand with a graver, a chisel with a toothed blade.

-

CHISELLING

This is a finishing similar to the one above, with irregular grooves on the stone's surface. It is also carried out by hand, but with a flat chisel.

-

ROLLING/SCRATCHING

Gives the stone a coarse appearance with small parallel grooves of variable width and depth. If done mechanically it creates a regular looking surface, if done manually it will result in slightly undulating and alternated grooves.

-

GROOVED

Produces a pattern with a regular striped appearance made by the combination of subtle grooves alternating with crests. It is only done by machine although its appearance is inspired by traditional graver finishing.

-

SAW PLANE SURFACE

This creates a softening of the background colour of the material. Although it is not strictly a surface finish, it can be used as if it were the final finish.

-

SPLIT FACE FINISH

A finishing created by splitting the stone and normally with only the surface in view. The result is called spaccatello, and is most commonly used for external walls or cladding.